WAG-New energy vehicle bellows

Product Overview:

- Product Features

- Specifications

- Technical data

- Video

-

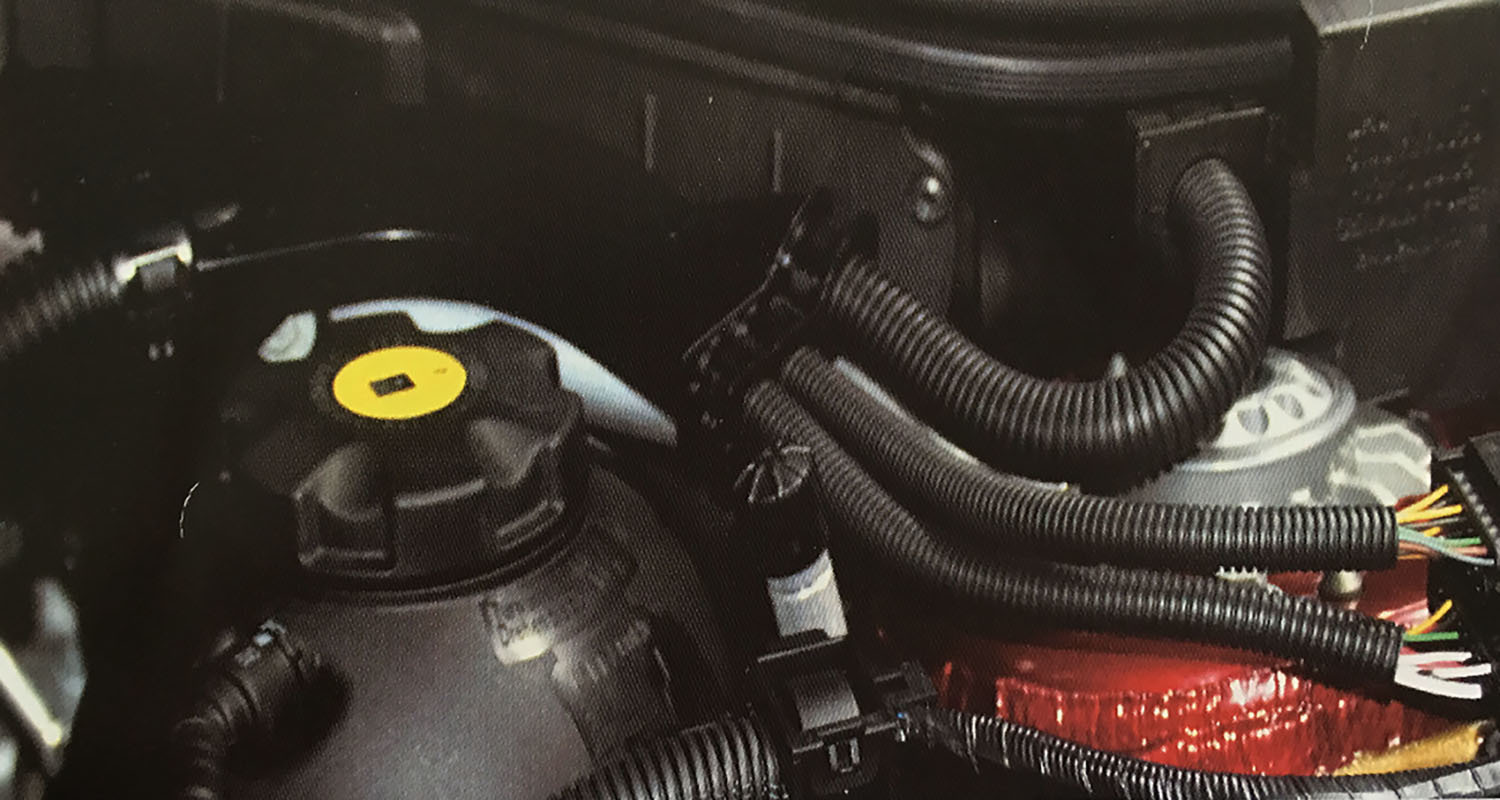

WAG-New Energy Vehicle Wiring Harness Protection Corrugated Hose

V0 flame-retardant and Split Corrugated Tube can be customized.

New energy vehicle Corrugated Hose have been widely used in New Energy Automobile industry, Bus ,machine tools, mechanical engineering, shipbuilding, communication lines, power engineering, electronic appliances, rail transit and industrial automation.

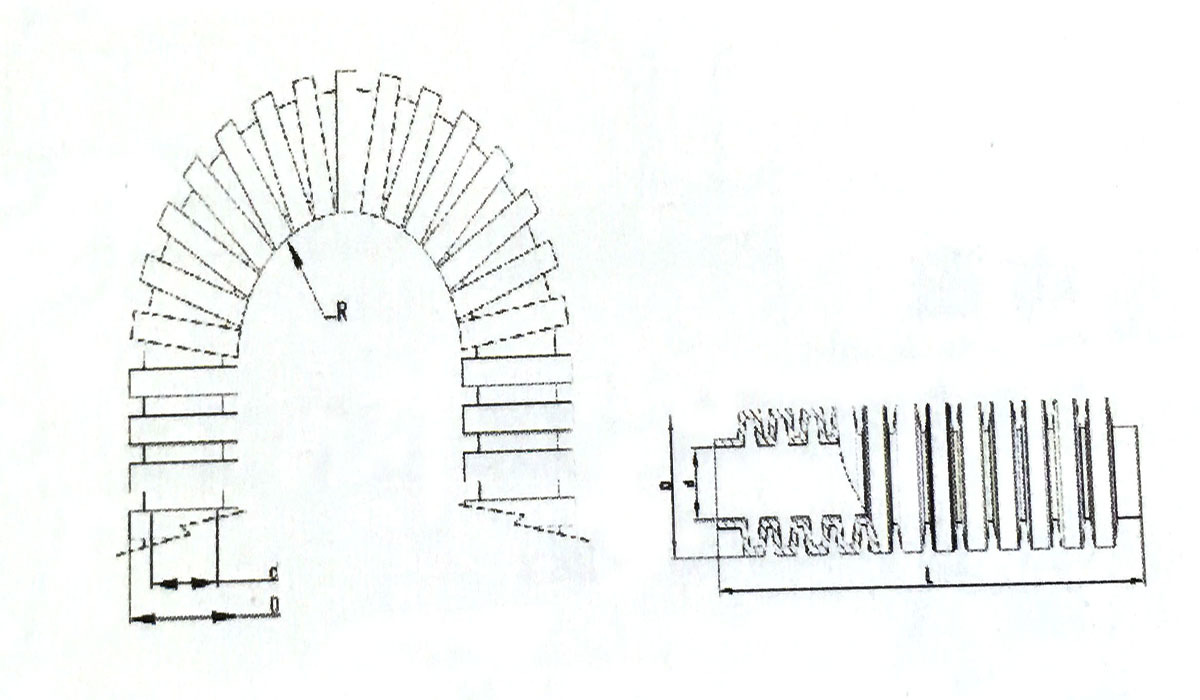

Drawing:

-

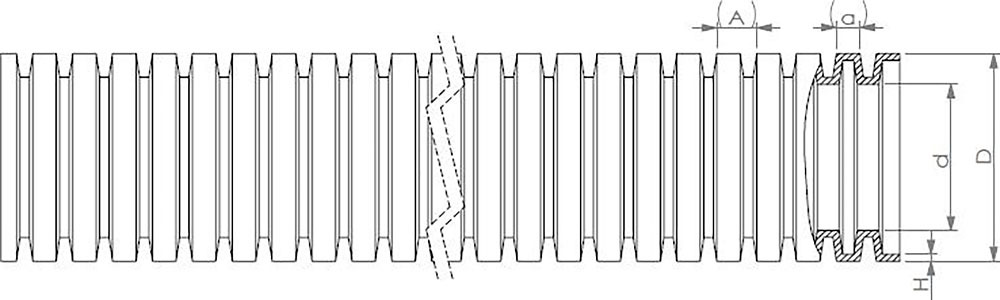

Specification :

SIZE

ID: d(MM)

OD: D(MM)

Thickness:

H(MM)

Wave spacing

A (mm)

Wave width

a(mm)

Packing

(M/Roll)

Φ 4.8*7

4.8±0.3

7.0±0.3

0.27±0.05

(2.1)

(1.45)

400

Φ 5.2*7.4

5.2±0.3

7.4±0.3

0.27±0.05

(2.1)

(1.45)

400

Φ 5.5*8

5.5±0.3

8.0±0.3

0.27±0.05

(2.1)

(1.45)

400

Φ 6*9

6.0±0.3

9.0±0.3

0.27±0.05

(2.5)

(1.75)

400

Φ 7*10

7.0±0.3

10.0±0.3

0.27±0.05

(2.7)

(1.95)

200

Φ 7.5*10.5

7.7±0.3

10.7±0.3

0.27±0.05

(2.7)

(1.8)

200

Φ 8.5*11.5

8.5±0.3

11.7±0.3

0.30±0.06

(2.7)

(1.95)

200

Φ 9*12

9.2±0.3

12.0±0.3

0.30±0.06

(2.7)

(1.95)

200

Φ 10*13

10.2±0.3

13.0±0.3

0.30±0.06

(2.7)

(1.95)

200

Φ 11*14

11.2±0.3

14.0±0.3

0.30±0.06

(2.7)

(1.95)

200

Φ 12*15.8

12.0±0.3

15.8±0.3

0.30±0.06

(3.2)

(2.3)

200

Φ 12.9*16

12.9±0.3

16.0±0.3

0.30±0.06

(3.2)

(2.15)

200

Φ 13*17

13.2±0.3

17.0±0.3

0.35±0.08

(3.2)

(2.3)

200

Φ 14.5*18.5

14.5±0.4

18.5±0.4

0.35±0.08

(3.2)

(2.3)

200

Φ 15.1*19.7

15.1±0.4

19.7±0.4

0.35±0.08

(3.2)

(2.3)

200

Φ 15.3*18.8

15.3±0.4

18.8±0.4

0.35±0.08

(3.2)

(2.25)

200

Φ 16*20

16.0±0.4

20.0±0.4

0.35±0.08

(3.2)

(2.3)

200

Φ 17*21.2

17.0±0.5

21.2±0.5

0.35±0.08

(3.6)

(2.45)

200

Φ 18*22

18.1±0.5

21.8±0.5

0.40±0.08

(3.2)

(2.15)

200

Φ 19*23.5

19.0±0.5

23.5±0.5

0.40±0.08

(3.35)

(2.3)

200

Φ 19.5*24.3

19.5±0.5

24.3±0.5

0.40±0.08

(3.5)

(2.3)

200

Φ 20*25

20.5±0.5

25.0±0.5

0.40±0.08

(3.1)

(2.35)

100

Φ 21*25.5

21.5±0.5

25.5±0.5

0.40±0.08

(3.3)

(2.3)

100

Φ 22*26.8

22.0±0.5

26.8±0.5

0.40±0.08

(3.1)

(2.3)

100

Φ 23*28.5

23.2±0.5

28.5±0.5

0.40±0.08

(3.2)

(2.3)

100

Φ 25*32

25.5±0.5

32.0±0.5

0.40±0.08

(4.5)

(2.75)

50

Φ 26*31

26.0±0.5

31.0±0.5

0.45±0.10

(3.1)

(2.3)

50

Φ 29*34.5

29.0±0.6

34.5±0.6

0.45±0.10

(3.5)

(2.35)

50

Φ 32*36.8

32.0±0.6

37.0±0.6

0.45±0.10

(3.3)

(2.35)

50

Φ 36*42.5

36.0±0.6

42.5±0.6

0.50±0.12

(4.15)

(3.0)

50

Φ 40*45

39.8±0.6

44.5±0.6

0.50±0.12

(4.15)

(2.85)

50

Φ 48*54.5

48.0±0.8

54.5±0.8

0.50±0.12

(4.3)

(3.0)

25

Φ 56*67.2

56.0±1.0

67.0±1.0

0.60±0.15

(6.7)

(4.0)

20

Φ 66*80

66.5±1.0

80.0±1.0

0.65±0.15

(8.5)

(5.0)

15

Φ 91*106

91.0±1.0

106.0±1.0

0.70±0.20

(8.5)

(5.2)

10

Note: Wave spacing A and wave width a are reference values.

Color : Black/Orange (conventional), other colors can be customized.

-

Temperature resistance : 150 degrees Celsius

Item

project

Performance

Test Methods

1

Tensile Strength(MPa)

PA≥60

ASTM D 2671

2

Elongation at break(%)

PA≥180

ASTM D 2671

3

Low temperature impact performance

After -40℃*4H,

No cracks and embrittlement in impact test

Steel ball:weight: 300g,

height: 100mm

4

Low temperature bending

After-40℃*4H

No cracks and embrittlement in bending test

Wrap around a round rod for 5 minutes to test

5

Moisture content

≥3.5%

Weighing method

6

High temperature deformation

Deformation rate ≤10%

Heat distortion temperature * 24h

7

Heat resistance

The tube not brittle

Heat distortion temperature * 240h

8

Aging performance

No brittleness, no powdering

Operating temperature *3000h

9

Flame retardant performance

Vertical combustion-V0, horizontal combustion-HB

GB/T 2408-2008

10

Burning rate

≤100mm/min

GB 8410-2006

11

Resistant to chemical reagents

The appearance is not allowed to be abnormal, and there should be no cracks in the bending

I a solution with a hydrochloric acid content of 10% or in a solution with a base content of 10%

Invasion (1h)

12

Oil resistant

No abnormal appearance is allowed, no cracks appear in bending

Gasoline, diesel, engine oil, hydraulic rotation,Transmission oil and engine coolant are soaked at room temperature for 20h

13

Copper corrosion

Does not corrode

UL 224

14

Protection level

IP68

-