TPU Aerator membrane/TPU membrane

Product Overview:

- Product Features

- Specifications

- Technical data

- Video

-

TPU Aerator membrane /TPU membrane

The physical and chemical performance, economy and life of the aeration system largely depend on the properties of the membrane. Such as pressure loss and uniformity, hydrolysis resistance, environmental protection, non-toxicity, etc.

TPU Tube Aerator Membrane is based on the customer's project status feedback over the years, combined with the characteristics of the sewage treatment situation, and optimized the ratio of raw materials, thereby upgrading and improving an aeration diaphragm tube, the aeration bubbles are tiny , uniform air distribution, effectively reducing the shear damage of air bubbles on active pollution particles, improving systemic activity and service life, and at the same time achieving the purpose of environmental protection.

Hydrolysis resistant TPU hose(Tubing) Supply of fine air bubbles; Oxygen for activated sludge nitrification; Continuous/intermittent gas supply system; Oxygen delivery before biological reaction and fixed bed; Mixing and stirring of activated sludge tanks (municipal and industrial wastewater); Grit tank ventilation; Aerobic aeration tank Aeration; water re-restoration systems; aquaculture, etc.

-

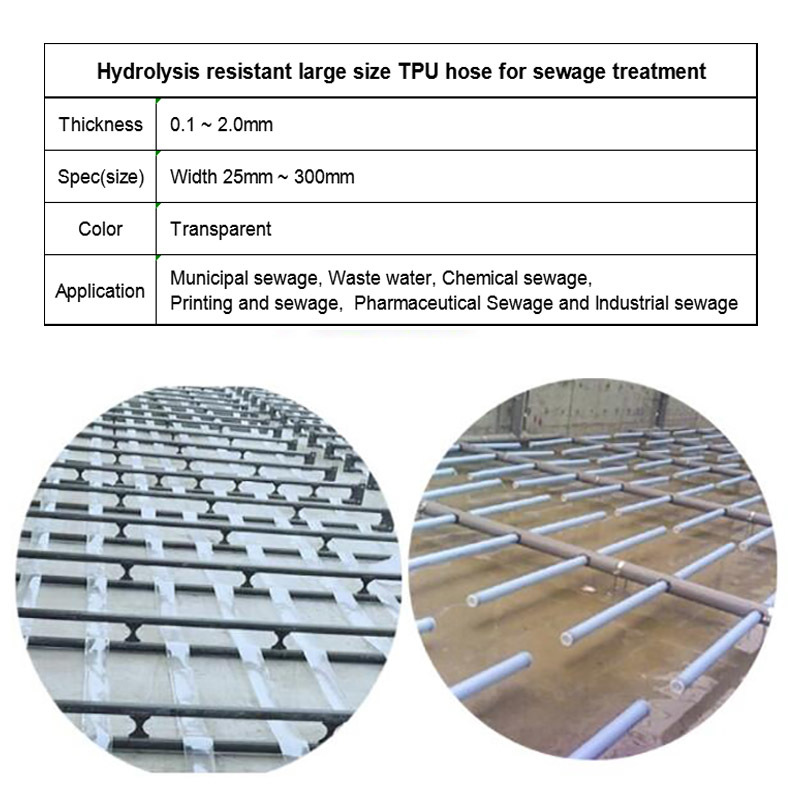

Commonly used specifications:

Width 185MM, width 145MM, width 100MM......etc., can be customized according to customer requirements.

-

Technical Parameter:

1. Compared with EPDM and silica gel on the existing market, it is more energy-saving due to high efficiency and low pressure loss;

2. There is no softener in the TPU diaphragm, and the service life is long and unbroken;

3. Wider ventilation range: normal ventilation: 3Nm-2/h • m - 8Nm-2/h • m , minimum ventilation up to: 1 Nm-2/h • m, maximum ventilation up to 1 Nm-2/h • m ,, up to 18 Nm-2/h • m when flushing with atmospheric volume;

4. More oxygen can be obtained relative to the same aeration density;

5. Fine and consistent bubble size;

6. Excellent tear and abrasion resistance (2.5 - 4 times mechanical strength, higher than most EPDM and silicone;

7. Excellent chemical properties;

8. Excellent resistance practicality in municipal and industrial;

9. Resistance to microbial hydrolysis, oil resistance, water resistance, mold resistance;

10. Good recyclability; -